Environmental stewardship is a core value at U. S. Steel, stemming from the Gary Principles created in the early 1900s and continuing today in our S.T.E.E.L. Principles.

Environmental stewardship is a core value at United States Steel Corporation, firmly embedded as one of our S.T.E.E.L. Principles. We know we must operate our facilities in an environmentally-responsible manner and take steps to protect and preserve our shared natural resources. As a company, U. S. Steel articulates our core value of environmental stewardship through three basic principles that are the responsibility of all our employees and our operations.

THESE PRINCIPLES ARE:

- Compliance with environmental laws and regulations

- Continuous improvement in environmental and resource managementand

- Continued reduction of GHG emissions through innovation

Approach of USSK’s parent company – United States Steel Corporation,

to the reduction of CO2

Reducing our greenhouse gas emissions is key to becoming a sustainable steel producer.

Producing steel is carbon-intensive and we have a roadmap to get to net-zero Scope 1 and Scope 2 emissions by 2050. Approximately 70–80% of the GHG emissions from integrated steelmaking are associated with the use of coke and coal to melt iron in blast furnaces.

U. S. Steel has always strived to be on the leading edge of the most energy-efficient production of steel using blast furnaces. Simultaneously, we are making steel by melting recycled steel scrap using electricity in EAFs, which produces significantly less GHG emissions. U. S. Steel recognizes the importance of having both routes of steel production while transitioning to a lower carbon economy.

In 2022, we reduced our absolute Scope 1 and market-based Scope 2 emissions by about 2.9 million metric tons when comparing 2022 to 2021 and started construction of our second EAF flat-roll mini mill, located near BRS in Osceola, Arkansas. This mill is expected to be operational in 2024.

Achieving carbon emissions reductions means remaining accountable to our long-term vision for a climate-friendly future across our value chain. We partnered with various organizations in 2022 to help us make progress towards our emissions reduction goals.

- A new Entergy Arkansas solar power plant is under development adjacent to the BRS mill in Osceola, Arkansas. The 250-megawatt Driver Solar plant in Osceola will be the utility’s largest solar facility and is expected to come online by 2025. It will generate renewable, emission-free energy for BRS with BRS receiving 100% of the facility’s environmental attributes. Entergy Arkansas is also providing other means of accessing renewable energy to support the achievement of U. S. Steel's long-term net-zero goal and will specifically reduce Scope 2 emissions.

- In another partnership with Entergy Arkansas, BRS installed 12 electric vehicle charging stations for employee vehicles. As part of the Entergy Arkansas eTech initiative, a portion of the installation qualifies for a utility rebate.

- Dell Technologies and BRS collaborated to make our data center carbon-neutral, while helping protect and restore the surrounding forest, by planting 2,000 trees in partnership with the Conservation Fund

- In cooperation with Shell US Gas & Power LLC and Equinor Holdings Inc., we are exploring regional decarbonization opportunities that feature carbon-capture utilization and storage as well as hydrogen production and utilization.

Along with strategic projects and partnerships across all our facilities, we continue to advance towards our GHG emissions reduction goals. We are committed to annual public reporting on progress against our GHG emissions reduction goals, as well as the measures being implemented to achieve them.

As we move full speed ahead toward reaching this target, we are focusing on process optimization as well as on the incorporation of EAFs into our footprint. Our greenhouse gas emission target reflects our continued commitment to improvement in production efficiency and the manufacture of products that are environmentally friendly.

GREENHOUSE GAS EMISSIONS

2030 GOAL

-20%

We have set a goal to reduce our

GHG emissions intensity by 20% by

2030 based on 2018 baseline

levels.

GREENHOUSE GAS EMISSIONS

2050 GOAL

NET-ZERO

We have set an ambitious goal

targeting net-zero carbon emissions

by 2050.

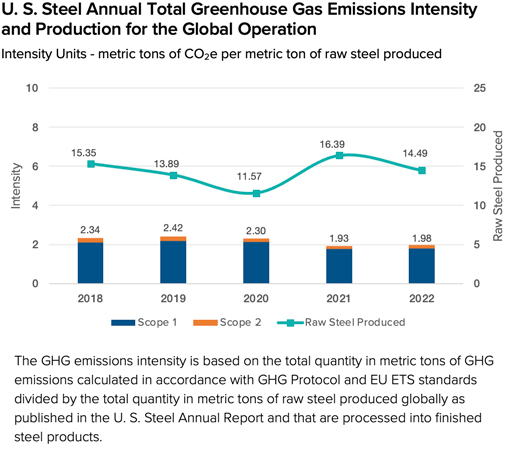

2022 TOTAL GREENHOUSE GAS EMISSIONS

The graphs below show the absolute and intensity based GHG emissions for U. S. Steel wholly owned facilities for 2018-2022. The results are separated by Scope 1, Scope 2, and total GHG emissions for North America, Europe and Total Global Operations. Absolute measurements are presented as metric tons of CO2e, while intensity measurements are metric tons of CO2e per metric ton of raw steel produced. Note: The emissions from Big River Steel are not included within these numbers because that acquisition didn’t occur until January 2021.

SPOTLIGHT: GHG EMISSIONS REDUCTION PROJECTS

BLAST FURNACE

RAW MATERIAL RANKING

U. S. Steel Košice completed the installation of a computer model that ranks the blast furnace charge materials in order of emission potential. This allows operations to be adjusted to reduce the amount of carbon dioxide emitted. This ranking program has reduced annual greenhouse gas emissions by up to 69,000 tonnes annually.